1) Main failure forms of rolling bearings.

Material defects, improper processing or assembly, poor lubrication, moisture and foreign matter invasion, corrosion and overload of rolling bearings may lead to early damage to bearings. Of course, in time when the installation, lubrication and use and maintenance are normal, after a period of operation, the bearing will also appear fatigue spalling and wear.

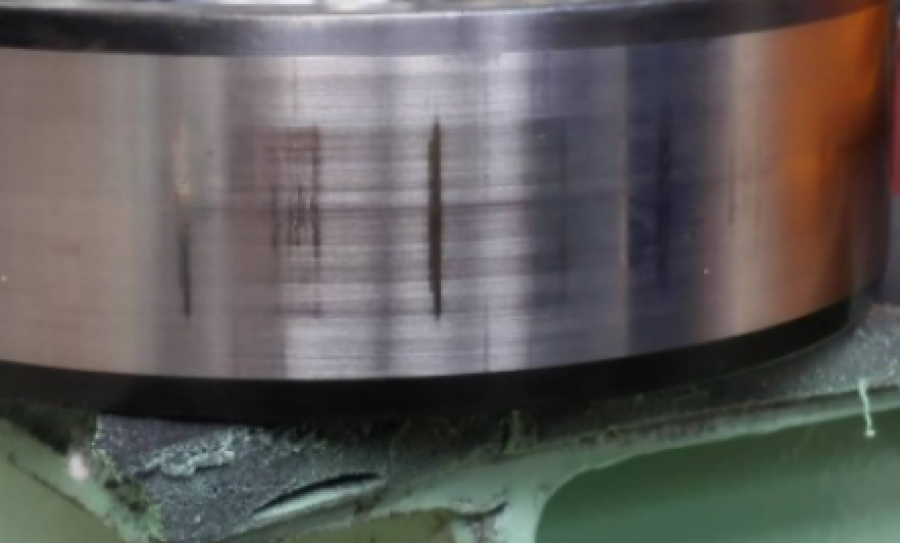

Rolling bearing failure has many forms, such as spalling, pitting (fatigue) crack, fracture, fouling, wear, softening, indentation, micro-vibration grooving and corrosion.

To accurately judge the bearing failure form, it is necessary to carefully inspect the failed parts; For complicated reasons, it is also necessary to analyze the materials and make a comprehensive analysis of the manufacturing, installation, use, operation and other conditions.

2) How to use and maintain rolling bearings

(1) Avoid bearing injury

The coupling should be installed by the hot sleeve method, not by hammering cold, which will damage the cage and raceway. The spalling on the raceway surface of the inner ring of deep groove ball bearing is caused by the development of indentation caused by impact load during installation.

Avoid indentation when installing bearings; After the motor stops running (or in the long-term storage process), it should be turned regularly to avoid indentation; When lifting the motor, it should fall smoothly to avoid indentation.

(2) Avoid bearing water intake and grease deterioration. When the motor is placed on the project site for a long time, it is necessary to avoid the loss of injector and oil pipe; Ensure that the fastening bolt of the bearing device and the temperature probe are tightened.

(3) Use clean grease and replace the grease regularly. Especially after the motor is stored for a long time, the old grease should be thoroughly cleaned and replaced with a new grease.